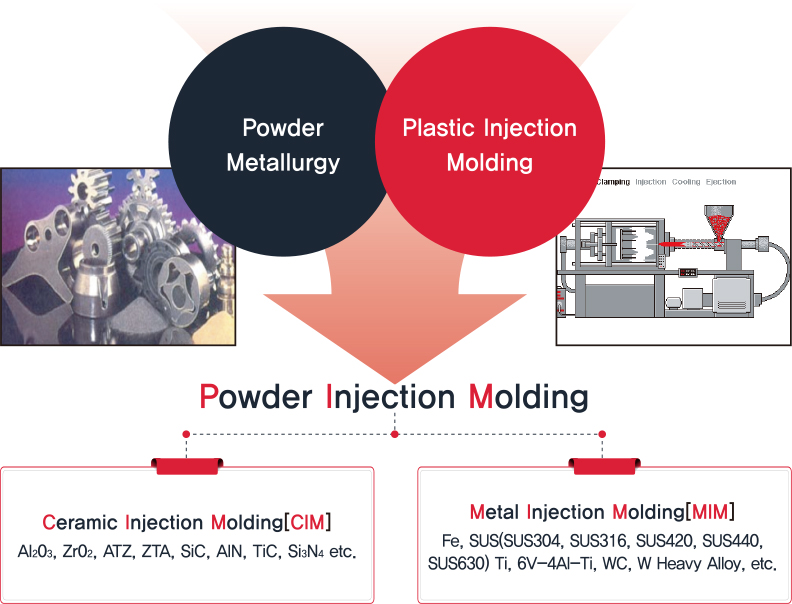

분말사출성형 Powder Injection Molding

- Technology suitable for mass production of three-dimensional complex parts Molding.

- High Density of Sintering Part : > 96%

- Suitable for the production of parts that are difficult to machine and have expensive raw materials.

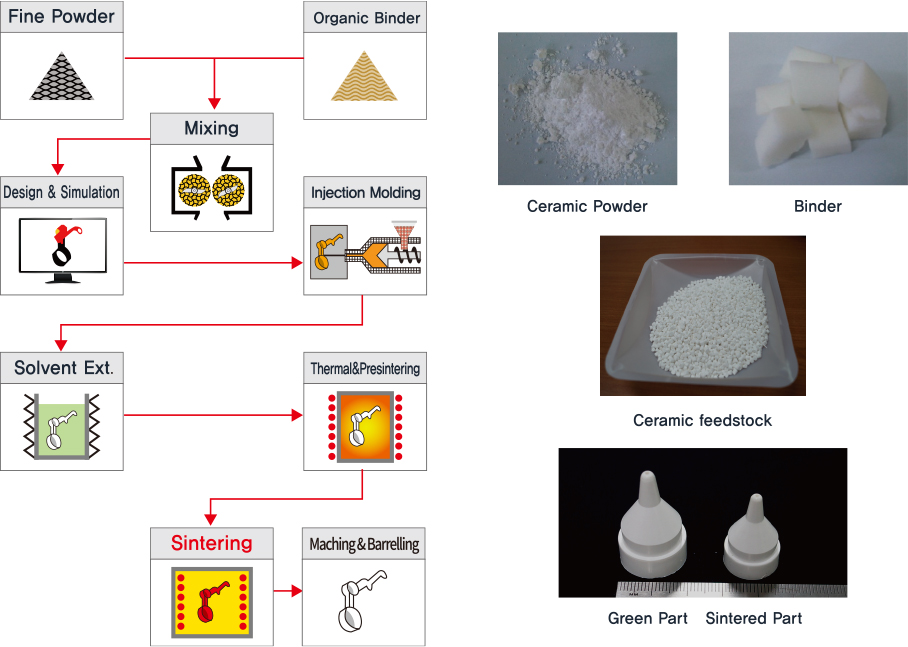

분말사출성형 제조공정 Manufacturing Process of PIM Technology

분말사출성형공정의 성능 및 일반공차 Performance and General Tolerances

| 성능 Capability |

|---|

| Major Dimensions |

<100mm |

|---|

| Wall Thickness |

0.2-10mm |

|---|

| Maximum Weight |

100g(1000g) |

|---|

| Surface Finish |

0.4~1.6㎛ |

|---|

| Flatness |

0.3% |

|---|

| 일반공차 General Tolerances |

|---|

| Nomal Dimensions |

Tolerance |

|---|

| 5mm |

±0.025mm |

|---|

| 10mm |

±0.05mm |

|---|

| 20mm |

±0.10mm |

|---|

| 40~60mm |

±0.25mm |

|---|

| >60mm |

±0.5% |

|---|

- The performance and general tolerances of the PIM process can be further improved by the development of mold processing and post-processing.